With many material components issued for service at CERN operating at cryogenic temperatures, the need for understanding their mechanical properties whilst subject to these conditions are crucial for progress at CERN.

MM section is equipped to perform mechanical tests at cryogenic temperatures, the most common being tests at 77 K (boiling temperature of liquid nitrogen at ambient pressure) and 4 K (boiling temperature of liquid nitrogen at ambient pressure). The tests with liquid Helium are performed in closed circuit, by connecting the He dewar, the cryostat and a recovery line to circulate. After its use in the test, the He gas is back to the CERN Central Helium Liquefier.

Properties of materials vary considerably with temperature. The mechanical behavior at cold temperature of metallic alloys depends generally on their crystalline structure and other microstructural specificities. Thus, when the application of some systems or components is designed to happen at cryogenic temperatures it is of crucial importance to characterize the mechanical properties of the materials (such as yield and ultimate strength, elastic modulus, ductility, fracture toughness,...) in such conditions.

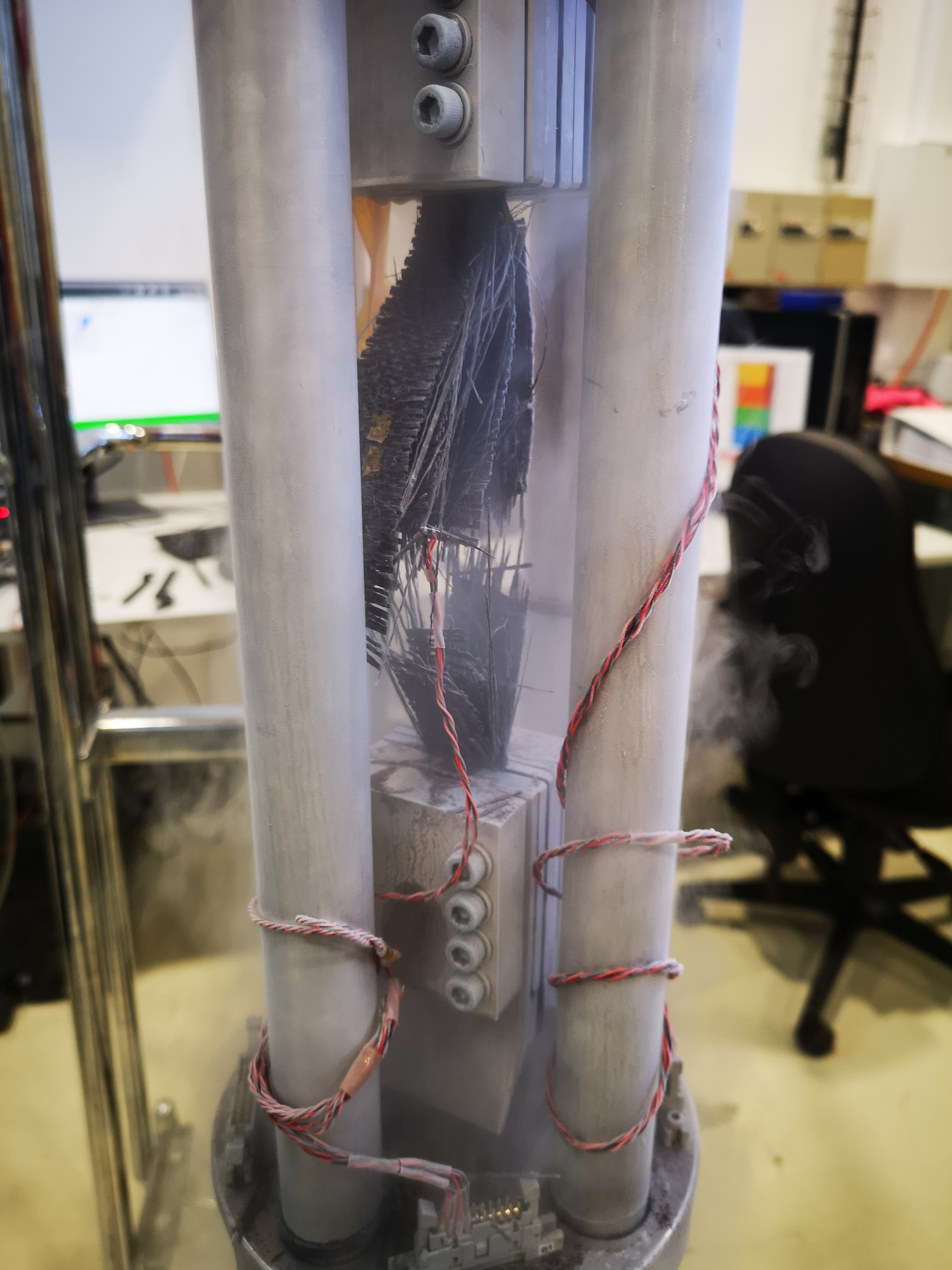

- Cryostat for 77 K testing. Capable of withstand a load of 200 kN in tension or compression.

- Cryostat for 4 K testing. Maximum load 100 kN in tension. Tensile and fracture mechanics tests can be performed in this cryostat.

Moreover, a new cryostat for testing at 4 K is being designed in collaboration with MME group. The goal is to optimize some technical aspects like the ease of alignment, as well as some practical aspects like the reduction of He consumed during a test and the time required to mount and dismount the assembly.

|

|