Tensile test

A tensile test is one of the most fundamental and common types of mechanical testing. A tensile test applies tensile (pulling) force to a material and measures the specimen's response to the stress. From this test, we can obtain properties of much interest such as the modulus of elasticity, yield strength and strain, ultimate tensile strength, and elongation at break.

Compression test

Compression tests are used to determine a material’s behavior under applied crushing loads. They are typically conducted by applying compressive pressure to a test specimen (usually of either a cuboid or cylindrical geometry) using platens or specialized fixtures on a universal testing machine. This test is used to determine properties such as elastic limit, proportional limit, yield point, yield strength, and, for some materials, compressive strength.

Bend test

Bend testing, sometimes called flexure testing or transverse beam testing, measures the behavior of materials subjected to simple beam loading. It is commonly performed on relatively flexible materials such as polymers and composites, as well as part of qualification of metallic welds.

A bend test is performed by placing a specimen on two support anvils. The sample is bent through applied force on 1 (3 – point bending) or 2 (4 – point bending) loading anvils. In a 3-point test, the area of uniform stress is quite small and concentrated under the center loading point. In a 4-point test, the area of uniform stress exists between the inner span loading points (typically half the length of the outer span).

MM section houses two types of universal testing machines aimed at providing Tensile, Compression and Bend.

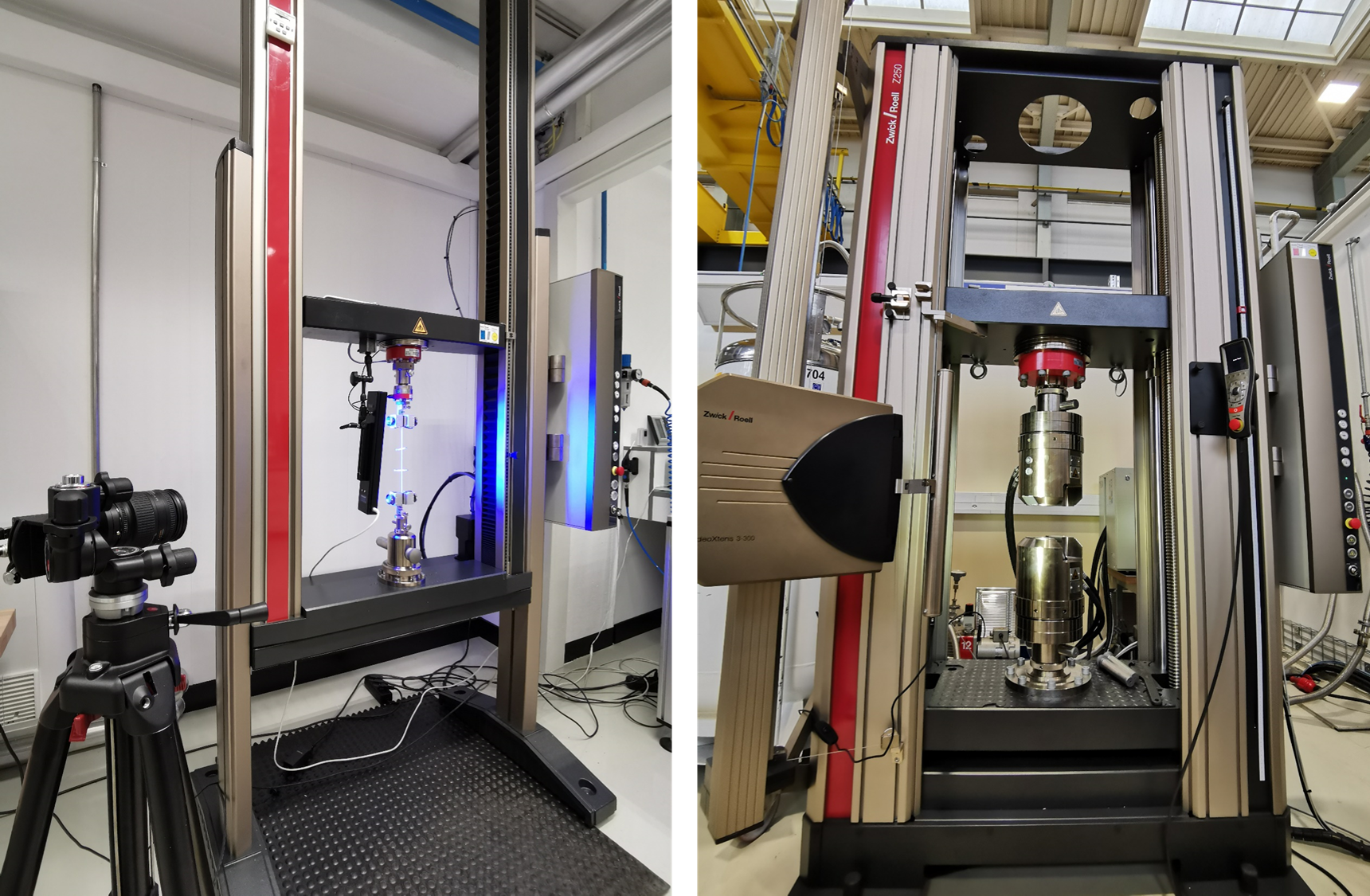

There are two models of these universal tests: ZwickRoell AllroundLine Z010 and ZwickRoell Z250. Each machine has different force application limits.

Universal Testing Machine ZwickRoell AllroundLine Z010 (10 kN)

Electromechanical testing machine for tensile, compression and bend tests at low forces and controlled environment (humidity and temperature). It is ideal for polymer testing and when a very accurate force control is required.

| Positioning, repetition accuracy on the crosshead | ± 2 µm |

| Force measurement | Class 0.5 / 1 (ISO 7500-1). |

| Load cells | 10 kN, 500 N |

| Crosshead speed of test load (vmin – vmax) | 0.0005 – 2000 mm/min |

Universal Testing Machine ZwickRoell Z250 (250 kN)

Electromechanical testing machine for tensile, compression and bend tests at moderate forces. It is ideal for testing metals, ceramics and large section specimens. Equipped with hydraulic grips, it is capable of performing tensile and compression in the same test. It is also equipped with an integrated video extensometer for contactless measurement of specimen’s deformation.

| Positioning, repetition accuracy on the crosshead | ± 2 µm |

| Positioning, repetition accuracy on the crosshead | ± 2 µm |

| Positioning, repetition accuracy on the crosshead | ± 2 µm |

| Force measurement | Class 0.5 / 1 (ISO 7500-1). |

| Load cells | 250 kN |

| Crosshead speed of test load (vmin – vmax) | 0.00005 – 600 mm/min |

Universal Testing Machines ZwickRoell AllroundLine Z010 and ZwickRoell Z250