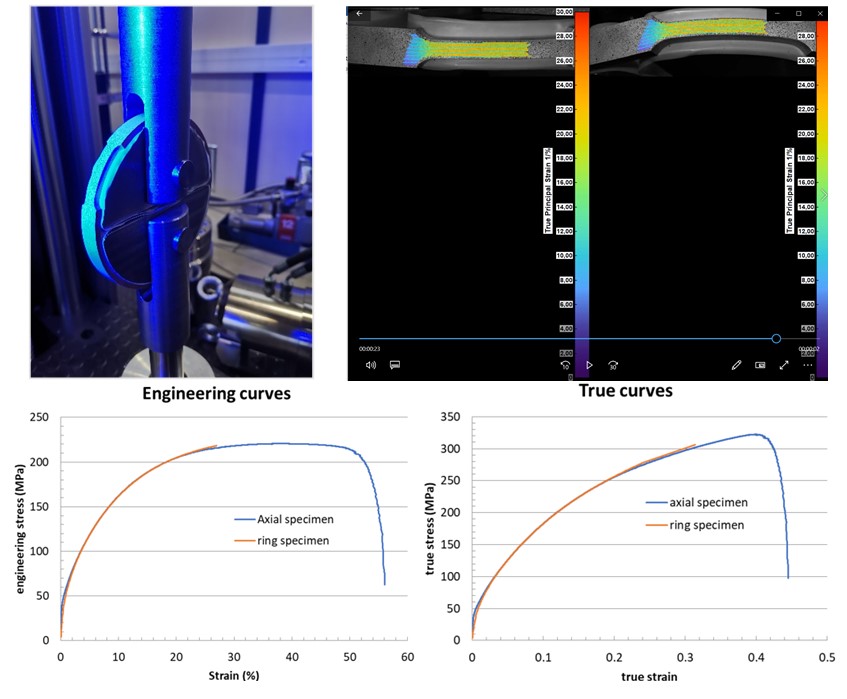

Digital Image Correlation (DIC)

Digital Image Correlation (DIC) is a contactless optical-digital extensometry technique, that can be used for a wide range of applications, for instance in mechanical testing.

The samples shall have a pattern on its surface that can be recognized by the DIC software. The principle of the technique is to record images from the sample surface during a test thanks to one or several cameras. The images are processed by a software, which is capable to calculate the relative displacements and strain fields over a surface, either globally or locally by creating virtual extensometers. This technique is capable of calculating different mechanical properties and visualize displacement and field strains in 3D.

Ring hoop tension test monitored by DIC system

Video extensometers (contactless)

- RTSS Video extensometer. It measures the longitudinal and transversal strain during material tests (e.g. tension, compression tests). The system can be used for flat and round specimen at field of view (FOV) of 10mm to 1000mm. Especially suitable for polymers and large deformations.

- Video extensometer VideoXtens. Provides non-contact measurement of tensile, compression, and flexural deformations of all types of plastics, metals, rubber, composites, and films, as well as two-dimensional point displacements within a matrix, e.g. on components. Integrated with ZwickRoell Z250 universal testing machine. It includes four high-resolution cameras. Thanks to array technology combines the fields of view of the cameras, thus providing large field of view with high resolution.

|

- Digital Image Correlation Limess Q400. Two digital cameras record the deformation process. The object surface has a stochastic (natural or prepared) pattern ("speckle pattern"). The method tracks the grey value pattern in small neighborhoods ("subsets" or "facettes"). The images are automatically evaluated using subpixel-accurate digital image correlation algorithms. This assigns the local surface pattern to the camera pixels and measures 3D coordinates, 3D displacements, 3D deformations and surface strains components.

- Flexible strain sensor for a wide application range

- Field of View of 1x1mm² to 10x10m²

- Easy usage and fully automatic calibration

- Integrated Analysis modules for automatic post processing

- Certifiable after ISO9513 (precision classes)

|

|

Mechanical extensometers (contact)

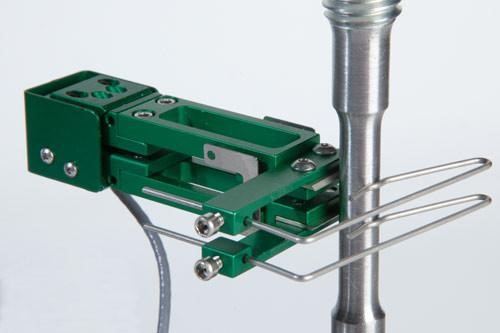

- MFA25. For tensile tests. They can track the deformation uni-axially by contact at room temperature. Gauge length: 25 to 75 mm. Extension range: 25 mm. Temperature range: 1 to 60°C. 0.5 Accuracy class EN ISO 9513

- EPSILON Model 3542. General-purpose strain gage extensometers for axial tensile, compression, and cyclic testing

- EPSILON Model 3442. Compact design, especially conceived to track the deformation uni-axially by contact at cryogenic temperatures

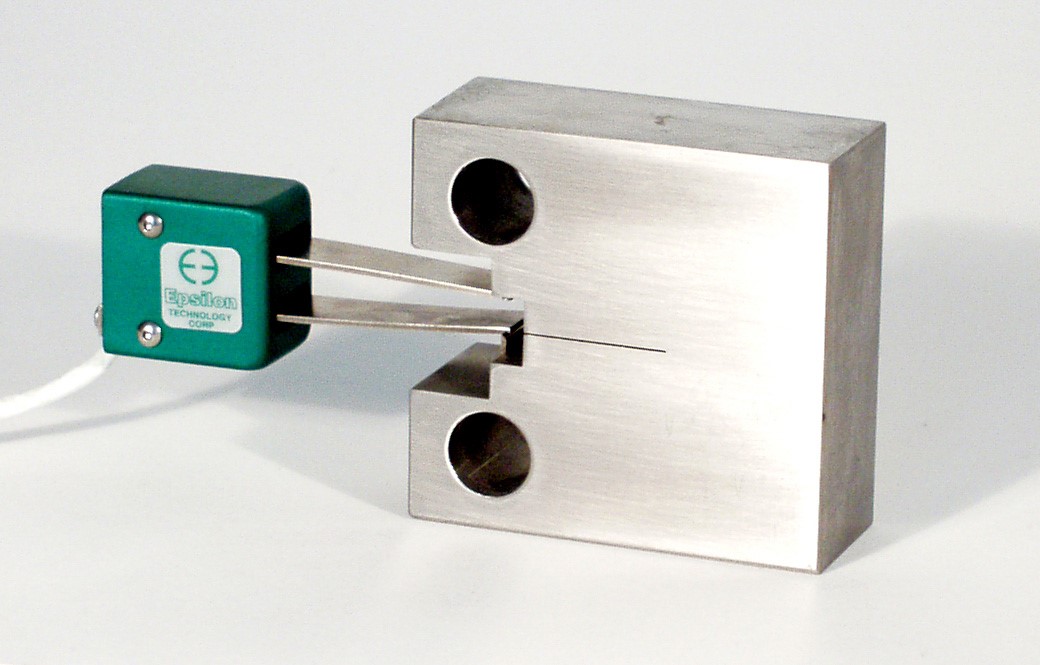

- EPSILON Model 3541. Allows performing all fracture mechanics tests at room temperature as well as cryogenic temperatures. Designed for determination of fracture mechanics parameters such as JIC, KIC, R-curve, fatigue crack growth rate (da/dN)

|

|